Hey there, everyone! I’ve got a fresh set of building plans to share with you today. I finally upgraded my miter saw bench and built a DIY mobile miter saw bench for my shop! It’s a huge improvement over the makeshift tabletop I had sitting on sawhorses. That was my life for the past 5 years, but not anymore. I finally have a proper bench to hold my miter saw, plus tons of cabinet space for storing other tools, and also a fence with flip stops to help me make those multiple cuts so much easier and accurate.

I’m teaming up with Rockler Woodworking and Hardware to share this project with you and I’ve also put together a YouTube video tutorial of the entire build, so be sure to check that out. Also, don’t forget to download the printable plans, which include the materials list and cut list for this project.

Let’s get started!

I cut my plywood pieces for the main carcass of the bench and began assembling it. I drilled 3/4″ pocket holes into the ends of the bench and attached them to the top and bottom with wood glue and 1 1/4″ pocket screws.

Next, I installed the center dividers. I used the rear stabilizing stretchers as blocks to help me determine the proper placement of the dividers and then glued and attached them in place with 1 1/4″ pocket screws.

I then installed the rear stabilizing stretchers with glue and 1 1/4″ pocket screws. These will give the bench stability and prevent any movement once it’s completed.

To add a little more support to the bottom of the bench, I ripped down 3″ strips of plywood to build a frame. I attached it to the bottom of the bench with 1 1/4″ wood screws and glue.

Once the bottom frame was attached, I added the casters. I used 3″ swivel casters for the middle of the bench and 3″ locking swivel casters for the outside corners.

I wanted the cabinets to have pull out shelves for easier access to my tools, and let’s face it, I really just didn’t want it to turn into a black hole where things get put away and they’re never seen again.

Once the pull out shelves were built, I installed the drawer glides to the bench. I used 22″ side mount drawer glides with a 100 lb capacity. I highly doubt I’ll ever even come close to reaching the weight limit on these slides, but it’s good to know that I can. Or that my youngest won’t break them if he’s in the middle of a game of hide and seek. By the way, the universal drawer slide jig from Rockler is pretty life changing. I bought it a few years ago when I was building my oldest son’s dresser and I love it!

For the cabinet doors, I marked and predrilled the holes, then installed the euro hinges. Pre-drilling the holes saves you a ton of time, rather than fumbling around with the screws. Sometimes my laziness will get the best of me and I won’t grab the drill to do this, but I always end up regretting it.

Next, it was time to build the frame for the table top. This will sit flush with the top of the miter saw base. To determine the height of your frame pieces, measure the height of your miter saw base. Measure the thickness of the plywood you are using for the top and subtract that from the miter saw base height to get the width of your frame pieces. Usually, plywood is a nominal thickness and not EXACTLY 3/4″, but mine was oddly right on the nose this time, so I cut my frame pieces at 3 3/4″ which will give me a table top height of 4 1/2″.

Because the miter saw base swings left to right for cutting angles, you’ll want to cut off the front corners of the table top to allow movement. I took down my measurements and cut the corners off with my jigsaw.

I attached the table tops with wood glue and 1 1/4″ wood screws.

To install the fence, I lined up my miter saw exactly where I wanted it to go, making sure that the fence on the saw was perfectly perpendicular to the ends of the bench. I used my carpenter’s square to line up the fence on the saw with my plywood fence, then clamped it into place using scrap wood. I glued and attached the fence with 1 1/4″ pocket screws.

Once the fence was in place, I added the double t-track fence cap and attached it with 5/8″ wood screws. The fence cap comes in 36″ lengths, but can be cut down to size. With the fences on the miter saw bench being 34″, I used my grinder to cut 1″ off each end of the track. You can cut 2″ off one end, but you’d end up cutting through one of the pre-drilled holes and it just wouldn’t look as aesthetically pleasing. I know it’s shop furniture, but cutting halfway through a hole and seeing it would have bothered me to no end.

Once the fence and t-tracks were installed, I bolted the saw to the bench. Unfortunately, the holes on my saw lined up right over the center dividers of the bench, so I couldn’t just simply drill holes and bolt the saw to the bench. Thankfully, the idea popped into my head to use threaded insert nuts and bolt it to the bench that way. Needless to say, I was feeling pretty proud of myself after that little epiphany.

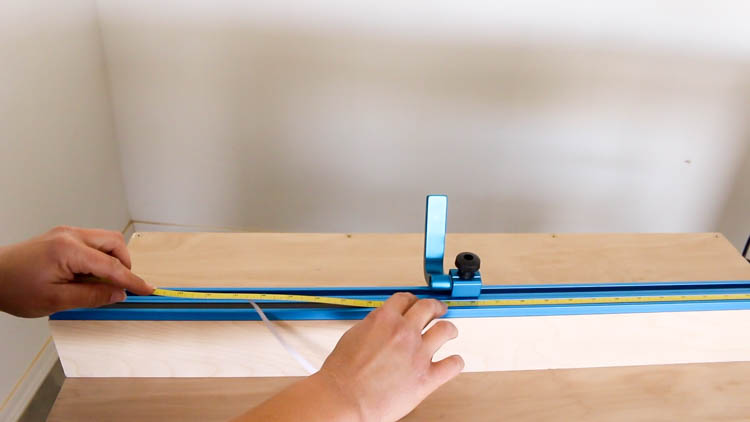

The tape measure insert is an optional accessory you can purchase for the t-track fence cap. The tape measure comes with a black plastic insert that slides into the t-track. It’s a very tight fit to get it in there and you may need to either shave the bottom, the edges, or both in order to make it fit. The tight fit ensures that your tape measure won’t move around when in use. Measure the distance between the miter saw blade and the edge of the t-track to determine where you should start your tape measure. For me, the blade was 14″ from the edge of the t-track, so I trimmed my tape measure at 14″, peeled off the adhesive backing and stuck it down to the black insert. I also slid the flip stops into place and the bench was done!

I’m so excited with how it turned out. It’s got so much storage space and I can’t wait to get things organized and put away in the cabinets. Having a level table top to the base will be such a huge game-changer for me. I have always just stacked scrap wood up to attempt to keep it level with the base, but it’s never been an ideal situation. Again, don’t forget to check out my YouTube video of the build and also download the printable plans!

If you’re still in the planning stages of your shop, make sure you pin this for later! Also, feel free to share your finished photos on social media and tag me (@addicted2diy) or email them to me (katie@addicted2diy.com). I love to feature reader projects!

For more shop furniture projects, check out the tutorial for my mobile cart for my Kreg Foreman. It has tons of storage for all of my Kreg tools, plus hidden dust collection!

DISCLSOURE: I was provided product and/or compensation for this post. All opinions and ideas are 100% my own. This post contains affiliate links. Should you purchase a product from one of these links, I may receive a small commission at no extra cost to you.

What a beautiful job very good idea

Thank you, Gail!

Doesn’t the metal backrest get in the way If you do a left hand 45%?

For this saw, you can only go as far as 40 degrees on the left side, and it doesn’t get in the way. In order to do a greater angle, the saw has to be removed from the cart to open the wings and increase the angle of the miter. It’s a rarity for me to use angles greater than 45 degrees, and most of them are right-hand angle cuts.

I really like this! I am going to try and give it a go…. I’m not the best with handy work but your instructions look really clear!

Thank you for the great post!

beau travail !

Very beautiful idea Katie. Love it. Keep it up.

Adnan recently posted…What is a Lathe Machine?

Thanks so much, Adnan!

Hi Katie,

Great build! I can’t read the measurements in your plans. Maybe it’s because I’m trying to view them from my phone, but they look super fuzzy.

Hi Marc,

I think the font may just be too small on the plans. I’ll have to fix them. If you’re really in a hurry to build the project, you can try printing the plans. The measurements may be a little easier to read. In the meantime, I’ll redo the plans with a larger font for the measurements.

Hi Katie,

I followed your instructions to the T, yet I’m having issues with unlevel floors in the basement causing the unit to flex and effectively changing the height of the support tables flanking the miter saw depending on the station’s location on the floor. Any ideas on how I could remedy this? Did you have any of these issues in the beginning?

Hey Katie,

Thanks for this. You have done a great job! Keep it up.

Sawyer recently posted…How to Change a Table Saw Blade

Hey Katie,

Thanks for this.You have done a great job! Keep it up.

Sawyer recently posted…How to Change a Table Saw Blade

Question: Can you make the fences removable? I want this to be a combination miter stand AND workbench. (It needs to do double duty.) So the fences would be in the way. Would it be reasonable to have some sort of bolt on, removable mechanism? Or is that just showing my naivete?

I hadn’t thought of that. I think you could, with a little creativity. Perhaps routing a groove for the fences to sit in and then securing them at the ends could work.